I kēia mau makahiki i hala iho nei, ua wikiwiki loa ka hoʻomohala ʻana o ka ʻoihana hana, a ua hoʻonui pū ʻia ka noi no ka hana metala.ʻO ka welding kekahi o nā kaʻina hana koʻikoʻi o ka hana metala, a ʻaʻole hiki i nā ʻano kuʻuna kuʻuna ke hoʻokō i nā pono o ka hana.Ma lalo o kēia manaʻo, kamīkini wiliwili lima limaUa hānau ʻia, i mahalo nui ʻia i ka wā i hoʻokuʻu ʻia ai, a ua hoʻololi koke i ka mākeke kuʻekuʻe kuʻuna.

ʻO kamīkini wiliwili lima lima limahe hanauna hou ia o nā lako wiliwili laser.No ka wiliwili ʻole pili.ʻAʻole pono ia i ke kaomi i ka wā o ka hana., ka mea e hoohehee ai i ka mea i loko, a maalili a crystallize e hana i weld.

a.ʻAʻole e hoʻokō ʻia ka ikaika o waho ma ka mea hana

I ka wā e hana ai ka mīkini wili laser lima lima i nā ʻāpana, no ka mea ʻaʻole ia e hoʻopili me nā ʻāpana i hana ʻia, ʻaʻohe koʻikoʻi o waho i nā ʻāpana i hoʻopaʻa ʻia i ka wā o ke kaʻina hana hoʻoheheʻe holoʻokoʻa, a ʻo ka manaʻo ikaika i hana ʻia e ka laser. kiʻekiʻe.He liʻiliʻi ka hopena wela ma ka puni o ka ʻāpana, no laila ʻaʻole e hoʻopōʻino ka ʻāpana i ka wā wili.

b.Hiki ke hoʻokō ʻia ka welding ma waena o nā mea like ʻole

I ka hana kuʻuna kuʻuna, ʻelua wale nō mea hana i hana ʻia i ka mea like hiki ke welded, akā ʻo ke kaʻina hana hoʻoheheʻe laser o ka mīkini kuʻi lima paʻa lima ʻaʻole hiki ke weld wale i ka helu heheʻe kiʻekiʻe a me nā mea like ʻole i paʻakikī ke hoʻoheheʻe a weld. , E like me ka titanium alloy, alumini alumini a me nā mea ʻē aʻe.Eia kekahi, hiki i ka ʻenehana hana welding laser ke ʻike i ka welding ma waena o kekahi mau mea like ʻole, e wāwahi ana i ka palena o ka welding ma waena o nā mea.

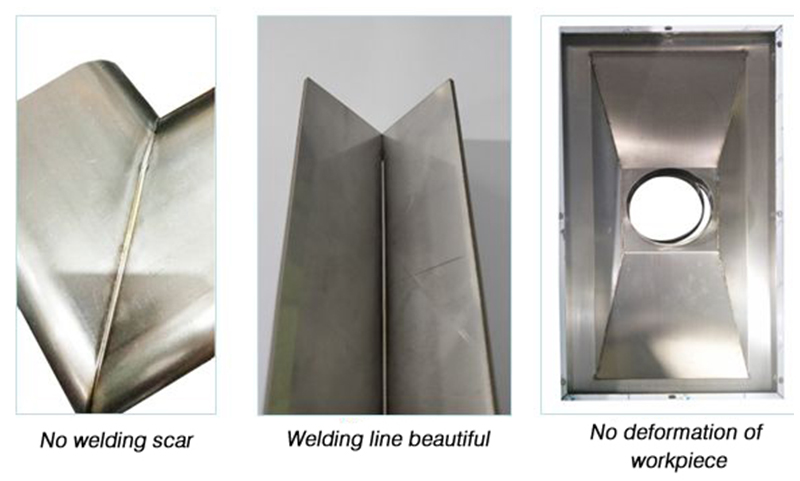

c.ʻO ka humu wili haiki, maʻemaʻe a nani ke ʻano

ʻO ka ʻenehana hoʻoheheʻe laser o ka mīkini welding laser paʻa lima he kiʻekiʻe loa, ʻaʻole wale ia e hoʻohaumia i ke kaiapuni, akā hana pū nō hoʻi i nā hui solder liʻiliʻi, nā wili kuʻi liʻiliʻi, ke ʻano kuʻi wili like ʻole, ka liʻiliʻi o nā pores a me nā hemahema, hiki ke hōʻemi a hoʻomaʻemaʻe i nā mea haumia makua, No laila, ma hope o ke kuʻi ʻana, ʻaʻole maikaʻi nā ʻano pale like ʻole, akā maikaʻi loa ka ʻili o ka mea.

Nā hiʻohiʻona omīkini wiliwili lima lima:

1. He liʻiliʻi ka nui o ka mea hana

2. ʻO ka hana maʻalahi a me ka maʻalahi, hiki ke hoʻomaopopo i ka hoʻopili ʻana i waho

3. ʻO ka maikaʻi o ka beam maikaʻi, ka wikiwiki wikiwiki, ka deformation thermal liʻiliʻi, ka pololei a me ka hoʻohui kiʻekiʻe

4. He nani, pālahalaha a me ka ʻole o nā pores, ʻaʻole pono ka mālama ʻana a i ʻole ka maʻalahi ma hope o ka wili.

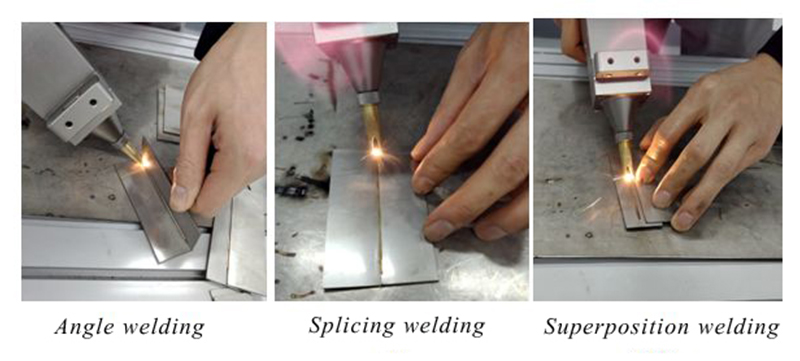

5. Hiki i ka pū wili lima paʻa ke wili i ka mea hana ma kēlā me kēia kihi, kahi kūpono no ka hoʻopaʻa ʻana i kahi o nā welds paʻakikī a me nā mea like ʻole.

Nā pōmaikaʻi o ka mīkini hoʻoheheʻe lima lima lima:

1. He mea maʻalahi ka hana a me ka maʻalahi o ka hoʻohanaʻana: he maʻalahi ka hana lima lima lima lima a he haʻahaʻa koina hana.

2. ʻO ka wikiwiki wiliwili wikiwiki: ʻO ka mīkini wili laser lima lima e hoʻomau mau ana, ʻo ka ikaika o ka beam, ʻoi aku ka maikaʻi a me ka wikiwiki kiʻekiʻe, ka liʻiliʻi o ka wahi wili, liʻiliʻi ka wahi i hoʻopili ʻia me ka wela, maʻemaʻe ka wili wili. a nani, a hoemi ia ka hana wili ana mahope.

3. Nā mea hoʻoheheʻe like ʻole: Hiki i ka mīkini hoʻoheheʻe laser lima lima ke wili i nā mea metala maʻamau e like me nā pā kila kila, nā pā hao, nā pā galvanized, a me nā pā alumini.

4. ʻO nā koi kaiapuni haʻahaʻa haʻahaʻa: ʻAʻole pono ka mīkini hoʻopaʻa lima lima lima i kahi papa wili kūikawā, noho nā mea hana i kahi wahi liʻiliʻi, a maʻalahi ka hana.Hoʻolako ʻia me nā mika o nā laina hoʻonui fiber optical, hiki ke hoʻoneʻe ʻia no nā hana lōʻihi me ka ʻole o ka palena o ke kaiapuni.

5. Hana hoʻomau: Ua hoʻolako ʻia ka laser me nā mea hoʻoheheʻe wai, hiki ke hōʻoia i ka hana hoʻomau kiʻekiʻe.

6. ʻO ke kumukūʻai kiʻekiʻe: ʻAʻole hiki i ka mīkini hoʻopaʻa lima lima lima ke hana i nā hana kuʻi, akā hoʻoponopono pū kekahi.ʻO ke ola o ka laser he 100,000 mau hola, ʻoi aku ka lōʻihi ma mua o ke ola lawelawe o nā mea hana maʻamau, a he kumu kūʻai.

Hoʻohālikelike o ka hoʻohana ikehu ma waenamīkini wiliwili lima limaa me argon arc welding:

Ke hoʻohālikelike ʻia me ka kuʻuna arc kuʻuna, ʻo ka mīkini hoʻopaʻa lima laser e hoʻopakele ma kahi o 80% a 90% o ka ikehu uila, a hiki ke hoʻemi ʻia ke kumukūʻai hana ma kahi o 30%.Hoʻohālikelike hopena hoʻohālikelike: hiki i ka mīkini hoʻopaʻa lima lima lima ke hoʻopau i ke kila like ʻole a me ka wili metala like ʻole.ʻO ka wikiwiki wikiwiki, ka liʻiliʻi deformation a me ka liʻiliʻi i hoʻopili ʻia i ka wela.He nani nā welds, palahalaha, a ʻaʻohe porosity.Welder laser paʻa lima no nā ʻāpana hāmama liʻiliʻi a me ka wiliwili.Hoʻohālikelike kaʻina hana ma hope: ʻO ka mīkini hoʻoheheʻe laser paʻa lima he haʻahaʻa wela haʻahaʻa a me ka liʻiliʻi deformation o ka mea hana i ka wā wili, a hiki ke loaʻa i kahi ʻili kuʻi nani me ka ʻole a i ʻole ka maʻalahi maʻalahi (e pili ana i nā koi hopena hopena).Hiki i ka mīkini wili lima lima lima ke hoʻemi nui i ke kumukūʻai hana o ke kaʻina hana polishing a me ka pae.

Nā kahua hoʻohana o ka mīkini hoʻoheheʻe laser paʻa lima:

ʻO ka mea maʻamau no ke kūlana paʻa o ka nui a me ka liʻiliʻi nui o ka metala, ke keʻena, ka chassis, ka puka alumini alumini a me ka puka makani, ke kīʻaha holoi kila kila a me nā mea hana nui ʻē aʻe e like me ke kihi ʻākau o loko, ka kihi ʻākau o waho, ka weld weld mokulele, ka wela liʻiliʻi. wahi i ka wā wiliwili, liʻiliʻi deformation, a me ka hohonu kuʻihao Nui a paʻa welded.Hoʻohana nui ʻia i loko o ka lumi kuke a me ka ʻoihana lumi ʻauʻau, ʻoihana mea hana hale, ʻoihana hoʻolaha, ʻoihana mold, ʻoihana huahana kila, ʻoihana ʻenekinia kila kila, ʻoihana puka a me ka puka makani, ʻoihana hana lima, ʻoihana huahana hale, ʻoihana lako, ʻoihana ʻāpana kaʻa, etc.

ʻO ka noi a me ka naʻauao onā mīkini wiliwili laserua lilo i mea hana ikaika i nā lako hana.ʻO ka hana hoʻoponopono kiʻekiʻe a me nā hiʻohiʻona hana maikaʻi o nā mīkini welding laser paʻa lima i hana i nā haʻawina kiʻekiʻe i ka hana ʻana o nā ʻoihana nui., ʻo ia hoʻi ke koho ʻana i nā mea kanu hana hou aʻe.

Ka manawa hoʻouna: Mei-10-2023